Wear parts that last 10x longer

Stop replacing parts every few weeks. Our wear parts outlast the OEM, protecting your equipment and your bottom line.

Good Earth Tools specializes in longer-lasting, better-performing wear parts for asphalt shingle manufacturing. Protected by durable and reliable tungsten carbide, our products easily outwork and outlast OEM parts, helping you cut downtime, speed up production, and boost your bottom line.

Let’s Talk Solutions

One tungsten carbide liner. over a million miles of shingle production.

Learn how Good Earth Tools used tungsten carbide to extend the life of a customer’s liners by 3000%, producing over a million miles of shingles (and counting) before requiring changeout.

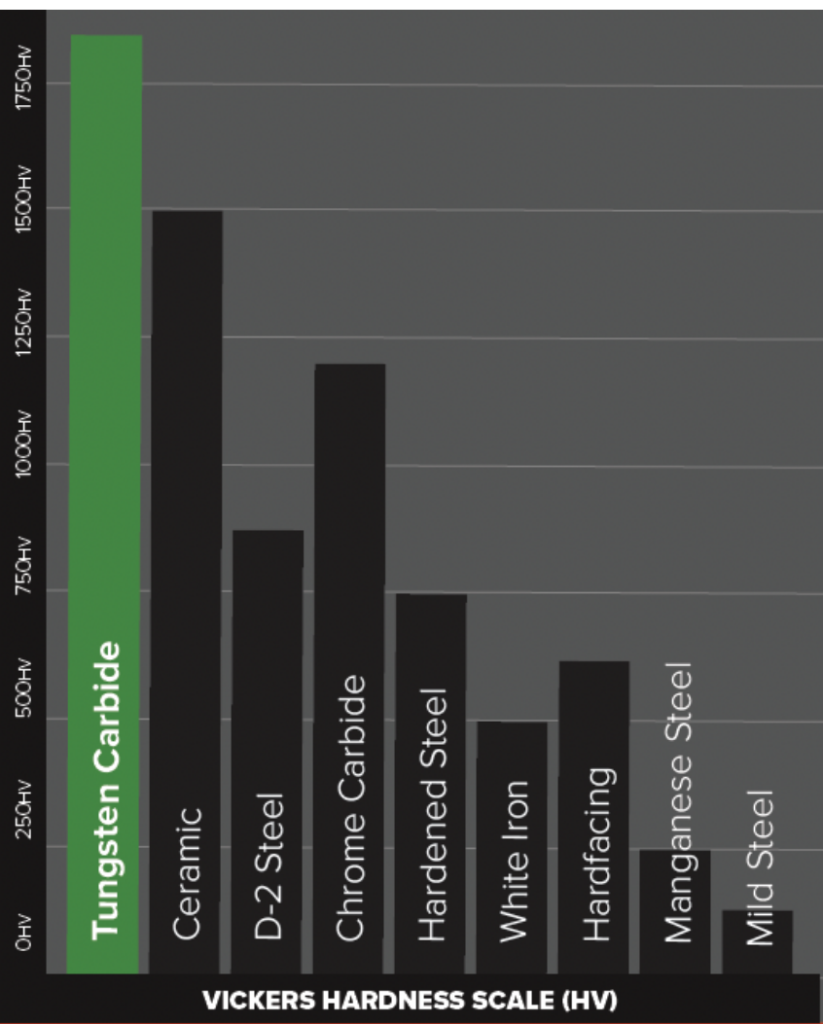

why choose Tungsten carbide?

It Saves Time and Money

In shingle manufacturing, wear parts are under almost constant abuse from liquid asphalt, metallic particles, and ceramic granules. OEM parts fail fast, and often. Good Earth Tools’ wear parts leverage our expertise in tungsten carbide—combining tungsten’s exceptional abrasion resistance with a precisely engineered binder system to create an incredibly strong bond. This ensures the tungsten carbide stays where it’s needed, maximizing service life and cost-effectiveness for a superior, long-lasting solution.

Better Across Every Key Metric:

Hardness

Second Only to Diamond

WEAR RESISTANCE

Outlasts Steel 25 to 1

HEAT RESISTANCE

Performs Up to 1000°F

DURABILITY

Up to 10x Longer Vs. OEM

Tungsten CARBIDE PROTECTION FOR EVERY HIGH-WEAR SURFACE

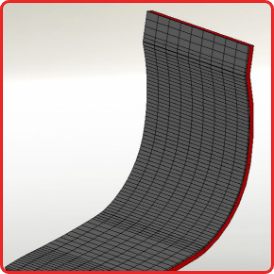

Wear Plates

Engineered to mitigate premature wear in critical areas

Diverters

Built to enhance efficiency and maintain production flow

Assemblies

Protects funnels from granule abrasion and constant wear

Guides

Made to ensure seamless movement without interruption

and more…

Don’t See It? We’ll Custom-Build It.

With a team of industry-leading engineers and full design and fabrication capabilities at our Missouri headquarters, Good Earth Tools is equipped to customize solutions to any and every wear-life problem.

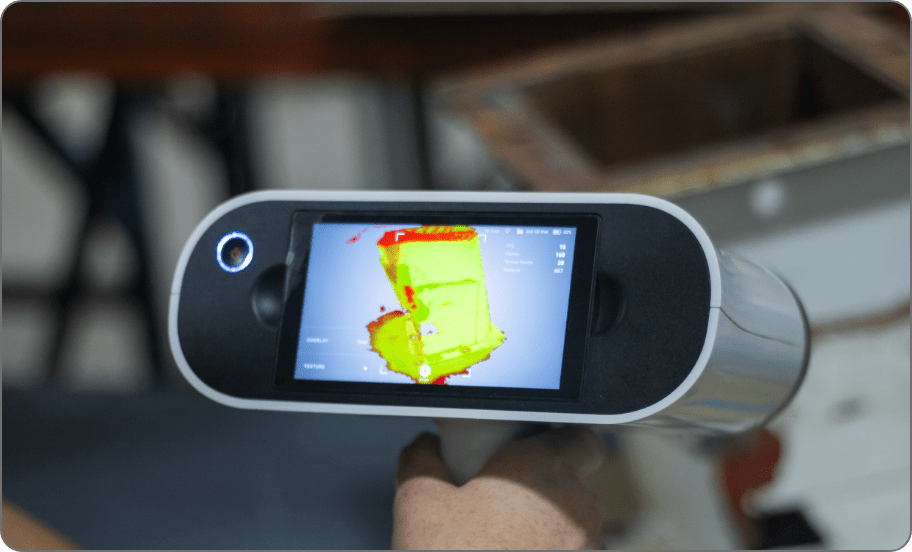

We use advanced 3D scanning to capture precise measurements at our customers’ facilities. Then we produce longer-lasting, better-performing solutions — whether it’s retrofits, replacements, or patch repairs — to those exact specifications.

Bring us your toughest wear problems. We'll customize tougher solutions.

Let’s upgrade your operation to maximize performance, durability, and longevity.

© 2023 Good Earth Tools | +1 636-535-2159 | Privacy Policy | ISO Certification